Product Introduction

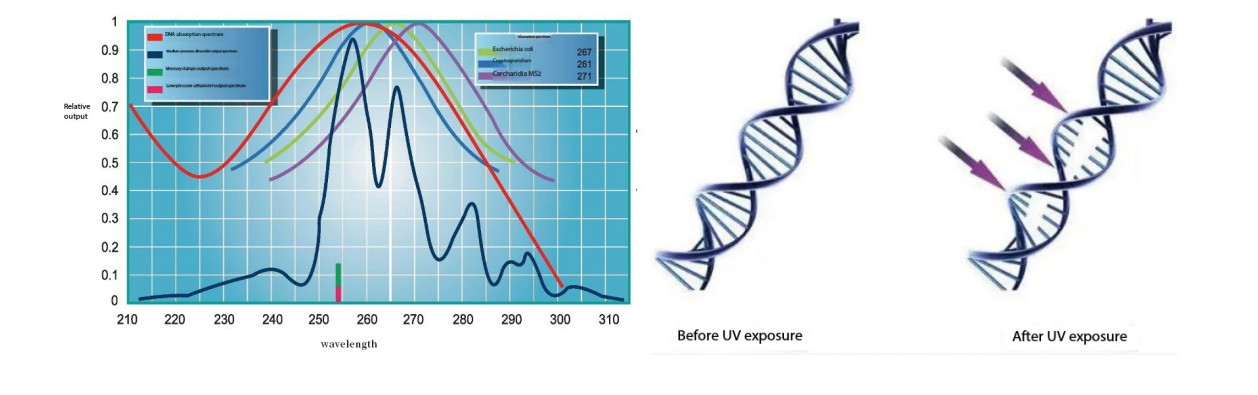

The core working principle of medium-pressure UV equipment is to emit ultraviolet rays covering a wide wavelength range (wavelength range 200nm~400nm), especially the UVC band (200~280nm) through a special medium-pressure mercury lamp. It can emit ultraviolet rays covering a wide wavelength range, including multiple bands that have significant effects on sterilization and decomposition of organic matter.

Ultraviolet rays can destroy the DNA or RNA structure of microorganisms, making them unable to reproduce and survive, thus achieving efficient sterilization and disinfection. In addition, the energy of ultraviolet rays can also cause the molecular bonds of organic matter to break and decompose organic pollutants, such as removing humus and odor substances in water.

Features

High durability light source system

The core is a medium-pressure mercury lamp, which has high power and wide spectrum output, and can continuously and stably emit full-band ultraviolet light. Some devices are also equipped with multiple mercury lamps to increase the intensity of ultraviolet radiation;

Reaction chamber

A properly designed reaction chamber ensures that the ultraviolet rays are evenly irradiated on the treated object, thus improving the treatment effect. The material used is usually a material with high ultraviolet transmittance and corrosion resistance, such as quartz glass.

Control System

Achieve precise control of equipment start, stop, running time, UV intensity and other parameters, automatic cleaning, easy operation and ensure stable operation of equipment;

Broad spectrum sterilization

Full-band ultraviolet rays can effectively kill a variety of bacteria, viruses, fungi, algae and other microorganisms, covering a wide range;

Efficient treatment of organic matter

Decompose organic pollutants in water, such as removing humus and odorous substances in water;

Quick response

Ultraviolet rays react quickly with microorganisms and organic matter, and can achieve the effects of sterilization and decomposition of organic matter in a short time;

No secondary pollution

The ultraviolet sterilization process is a physical action and will not produce secondary pollution like chemical disinfectants.

Technical advantages

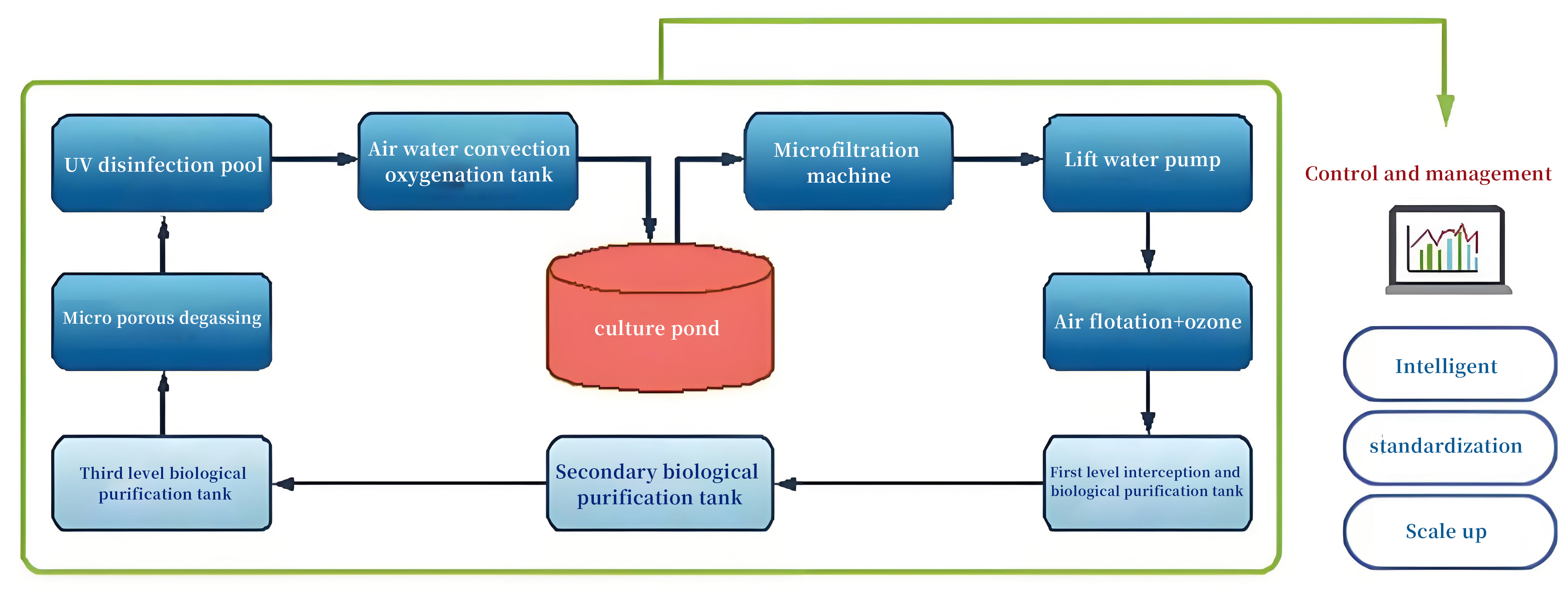

With the rapid development of aquaculture, the aquaculture industry is also facing health and safety issues due to water pollution and the presence of pathogenic microorganisms. In order to solve these problems, medium-pressure UV sterilizers are widely used in aquaculture environments.

★ Highly effective sterilization capability

Medium pressure UV sterilizer uses multi-spectral ultraviolet radiation to quickly and effectively kill common pathogens, viruses, parasites and other microorganisms in water. Its unique sterilization mechanism reduces the number of bacteria, algae and parasites, thereby reducing the risk of disease.

★ No chemical residue

Medium-pressure UV disinfection equipment does not require the use of any chemical agents, so no chemical residues will be produced. This is of great significance to the environmental friendliness and product safety of aquaculture. Consumers are increasingly concerned about food safety issues, and the use of medium-pressure UV disinfection can enhance the market competitiveness of aquatic products.

★ Improve water quality stability

The multi-spectrum disinfector eliminates turbidity, suspended matter and organic matter in the water, effectively purifies the water quality and maintains the stability of the breeding environment. Good water quality helps the growth and healthy development of aquatic animals, thereby improving breeding output and quality.

★Energy saving and environmental protection

Compared with traditional disinfection equipment, medium-pressure UV sterilizers have higher energy efficiency and low energy consumption. At the same time, it will not produce any pollutants to the water body and can be recycled. This energy-saving and environmentally friendly feature is in line with today's society's pursuit of sustainable development and actively promotes the sustainable development of the aquaculture industry.

Technical Parameters

|

Device Model |

Disinfection power |

Power of single lamp |

Number of lamps |

caliber |

Reference water volume (m³/H) |

Voltage supply |

|

GYZ-UUVC-1/1.0KW |

1KW |

1KW |

1 piece |

DN100 |

30-40 |

220V50Hz |

|

GYZ-UUVC-1/2.0KW |

2KW |

2KW |

1 piece |

DN125 |

60-80 |

380V50Hz |

|

GYZ-UUVC-1/3.0KW |

3KW |

3KW |

1 piece |

DN150 |

100-125 |

380V50Hz |

|

GYZ-UUVC-2/2.0KW |

4KW |

2KW |

2piece |

DN200 |

130-150 |

380V50Hz |

|

GYZ-UUVC-1/6.0KW |

6KW |

6KW |

1 piece |

DN250 |

200-250 |

380V50Hz |

|

GYZ-UUVC-3/3.0KW |

9KW |

3KW |

3piece |

DN250 |

300-350 |

380V50Hz |

|

GYZ-UUVC-2/6.0KW |

12KW |

6KW |

2piece |

DN300 |

300-350 |

380V50Hz |

|

GYZ-UUVC-3/6.0KW |

18KW |

6KW |

3piece |

DN350 |

350-400 |

380V50Hz |

|

GYZ-UUVC-4/6.0KW |

24KW |

6KW |

4piece |

DN400 |

400-450 |

380V50Hz |

.jpg)

1.jpg)

.jpg)

.jpg)