Features

High durability light source system

The core is a medium-pressure mercury lamp, which has high power and wide spectrum output, and can continuously and stably emit full-band ultraviolet light. Some devices are also equipped with multiple mercury lamps to increase the intensity of ultraviolet radiation;

Reaction chamber

A properly designed reaction chamber ensures that the ultraviolet rays are evenly irradiated on the treated object, thus improving the treatment effect. The material used is usually a material with high ultraviolet transmittance and corrosion resistance, such as quartz glass.

Control System

Achieve precise control of equipment start, stop, running time, UV intensity and other parameters, automatic cleaning, easy operation and ensure stable operation of equipment;

Broad spectrum sterilization

Full-band ultraviolet rays can effectively kill a variety of bacteria, viruses, fungi, algae and other microorganisms, covering a wide range;

Efficient treatment of organic matter

Decompose organic pollutants in water, such as removing humus and odorous substances in water;

Quick response

Ultraviolet rays react quickly with microorganisms and organic matter, and can achieve the effects of sterilization and decomposition of organic matter in a short time;

No secondary pollution

The ultraviolet sterilization process is a physical action and will not produce secondary pollution like chemical disinfectants.

Medium Pressure UV Applications in the Electronics Industry

TOC remover is used to remove TOC total organic carbon from ultrapure water. TOC total organic carbon is an organic medium that is difficult to degrade in ultrapure water, which affects the purity of ultrapure water used by the semiconductor industry to clean semiconductor materials or electronic chips. It has the following significant effects:

1.Total organic carbon residues in the product will cause the semiconductor material to degrade or fail;

2.Under certain conditions, total organic carbon undergoes oxidation reactions, causing oxidation and corrosion of semiconductor materials, damaging their structure and function;

3.When total organic matter remains in water, it forms small bubbles or tiny gas clusters that adhere to the surface of the product, damaging its structure and function.

The principle of ultraviolet light removing total organic carbon in ultrapure water

Photolysis : UV photons interact with water molecules, exciting them to generate highly oxidizing hydroxyl radicals (·OH), which can oxidize organic matter in water;

Direct photolysis : high-energy photons directly break the molecular chains of organic matter and decompose organic matter;

Ionization : UV photons break the molecular chains of organic matter, ionize it, and remove it through subsequent ion exchange;

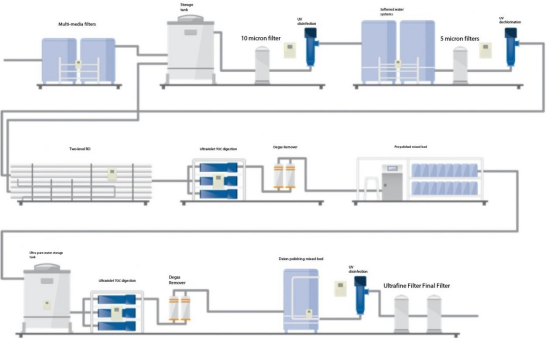

Medium pressure UV application process in the electronics industry

Technical Parameters

|

Device Model |

Disinfection power |

Power of single lamp |

Number of lamps |

caliber |

Reference water volume (m³/H) |

Voltage supply |

|

GYZ-UUVC-1/1.0KW |

1KW |

1KW |

1 piece |

DN100 |

30-40 |

220V50Hz |

|

GYZ-UUVC-1/2.0KW |

2KW |

2KW |

1 piece |

DN125 |

60-80 |

380V50Hz |

|

GYZ-UUVC-1/3.0KW |

3KW |

3KW |

1 piece |

DN150 |

100-125 |

380V50Hz |

|

GYZ-UUVC-2/2.0KW |

4KW |

2KW |

2piece |

DN200 |

130-150 |

380V50Hz |

|

GYZ-UUVC-1/6.0KW |

6KW |

6KW |

1 piece |

DN250 |

200-250 |

380V50Hz |

|

GYZ-UUVC-3/3.0KW |

9KW |

3KW |

3piece |

DN250 |

300-350 |

380V50Hz |

|

GYZ-UUVC-2/6.0KW |

12KW |

6KW |

2piece |

DN300 |

300-350 |

380V50Hz |

|

GYZ-UUVC-3/6.0KW |

18KW |

6KW |

3piece |

DN350 |

350-400 |

380V50Hz |

|

GYZ-UUVC-4/6.0KW |

24KW |

6KW |

4piece |

DN400 |

400-450 |

380V50Hz |

.jpg)

.jpg)

.jpg)