Features

High durability light source system

The core is a medium-pressure mercury lamp, which has high power and wide spectrum output, and can continuously and stably emit full-band ultraviolet light. Some devices are also equipped with multiple mercury lamps to increase the intensity of ultraviolet radiation;

Reaction chamber

A properly designed reaction chamber ensures that the ultraviolet rays are evenly irradiated on the treated object, thus improving the treatment effect. The material used is usually a material with high ultraviolet transmittance and corrosion resistance, such as quartz glass.

Control System

Achieve precise control of equipment start, stop, running time, UV intensity and other parameters, automatic cleaning, easy operation and ensure stable operation of equipment;

Broad spectrum sterilization

Full-band ultraviolet rays can effectively kill a variety of bacteria, viruses, fungi, algae and other microorganisms, covering a wide range;

Efficient treatment of organic matter

Decompose organic pollutants in water, such as removing humus and odorous substances in water;

Quick response

Ultraviolet rays react quickly with microorganisms and organic matter, and can achieve the effects of sterilization and decomposition of organic matter in a short time;

No secondary pollution

The ultraviolet sterilization process is a physical action and will not produce secondary pollution like chemical disinfectants.

High durability light source system

The core is a medium-pressure mercury lamp, which has high power and wide spectrum output, and can continuously and stably emit full-band ultraviolet light. Some devices are also equipped with multiple mercury lamps to increase the intensity of ultraviolet radiation;

Reaction chamber

A properly designed reaction chamber ensures that the ultraviolet rays are evenly irradiated on the treated object, thus improving the treatment effect. The material used is usually a material with high ultraviolet transmittance and corrosion resistance, such as quartz glass.

Control System

Achieve precise control of equipment start, stop, running time, UV intensity and other parameters, automatic cleaning, easy operation and ensure stable operation of equipment;

Broad spectrum sterilization

Full-band ultraviolet rays can effectively kill a variety of bacteria, viruses, fungi, algae and other microorganisms, covering a wide range;

Efficient treatment of organic matter

Decompose organic pollutants in water, such as removing humus and odorous substances in water;

Quick response

Ultraviolet rays react quickly with microorganisms and organic matter, and can achieve the effects of sterilization and decomposition of organic matter in a short time;

No secondary pollution

The ultraviolet sterilization process is a physical action and will not produce secondary pollution like chemical disinfectants.

Technical advantages

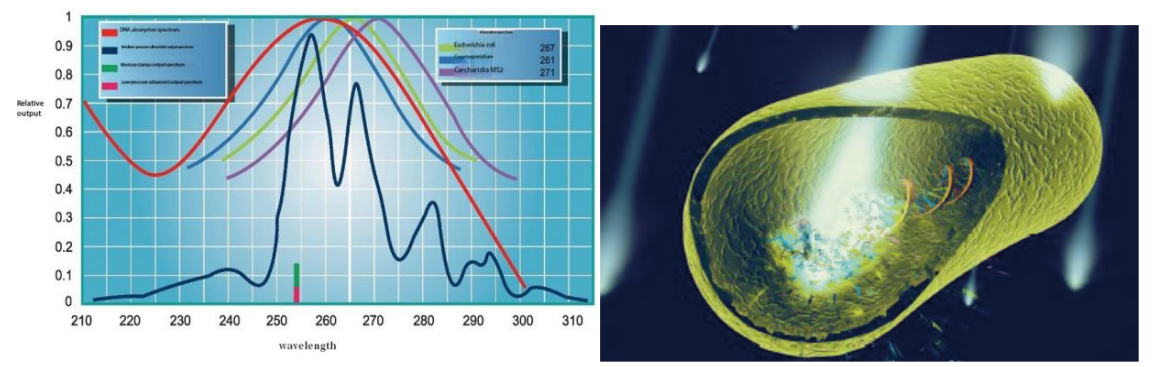

★ Broad spectrum bactericidal

Medium-pressure ultraviolet light outputs a continuous spectrum (wavelength range 200nm~400nm); low-pressure ultraviolet light only outputs a monochromatic spectrum with a wavelength of 253.7nm. Since different types of microorganisms and different structures of microorganisms have different absorption capabilities and sensitivities to ultraviolet rays of different wavelengths, medium-pressure multi-spectrum ultraviolet sterilization is more broad-spectrum;

★ More thorough sterilization

Medium-pressure multi-spectrum ultraviolet rays can completely destroy the structure of microorganisms and effectively avoid the problem of microbial photoreactivation; while low-pressure ultraviolet rays only destroy the DNA structure of microorganisms;

★ Wide adaptability to sterilization environment

Medium-pressure multi-spectrum ultraviolet sterilization is not affected by the temperature of the disinfection medium; while the optimal operating temperature range of low-pressure ultraviolet light is 5°C~40°C;

★Sterilization monitoring is more accurate

The maximum power of a single medium-pressure UV lamp can reach 12kw, and the maximum processing flow rate can reach 600m3/h; it can minimize the number of lamps used and improve monitoring accuracy.

* Ultraviolet light can damage the genetic material (DNA) of microorganisms, preventing them from replicating and infecting.

Process

Mineral water/natural water

Process advantages: Purely physical and green disinfection method, controlling microorganisms throughout the entire process; minimizing ozone concentration and effectively avoiding the formation of bromate.

Carbonated/Non-carbonated/Dairy Products and Beverages

Process advantages: Purely physical and green disinfection method, controlling microorganisms throughout the entire process; preventing microbial contamination of the RO system, reducing cleaning frequency, and extending membrane service life; in dairy beverage applications, it can replace water pasteurization and reduce operating costs.

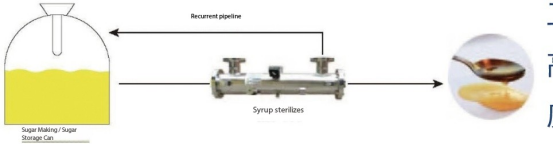

syrup

Process advantages: Highly efficient in killing spores and thermophilic bacteria in syrup; effectively lowering the sugar dissolving temperature and reducing energy consumption.

Technical Parameters

|

Device Model |

Disinfection power |

Power of single lamp |

Number of lamps |

caliber |

Reference water volume (m³/H) |

Voltage supply |

|

GYZ-UUVC-1/1.0KW |

1KW |

1KW |

1 piece |

DN100 |

30-40 |

220V50Hz |

|

GYZ-UUVC-1/2.0KW |

2KW |

2KW |

1 piece |

DN125 |

60-80 |

380V50Hz |

|

GYZ-UUVC-1/3.0KW |

3KW |

3KW |

1 piece |

DN150 |

100-125 |

380V50Hz |

|

GYZ-UUVC-2/2.0KW |

4KW |

2KW |

2piece |

DN200 |

130-150 |

380V50Hz |

|

GYZ-UUVC-1/6.0KW |

6KW |

6KW |

1 piece |

DN250 |

200-250 |

380V50Hz |

|

GYZ-UUVC-3/3.0KW |

9KW |

3KW |

3piece |

DN250 |

300-350 |

380V50Hz |

|

GYZ-UUVC-2/6.0KW |

12KW |

6KW |

2piece |

DN300 |

300-350 |

380V50Hz |

|

GYZ-UUVC-3/6.0KW |

18KW |

6KW |

3piece |

DN350 |

350-400 |

380V50Hz |

|

GYZ-UUVC-4/6.0KW |

24KW |

6KW |

4piece |

DN400 |

400-450 |

380V50Hz |

.jpg)

.jpg)

.jpg)

.jpg)