Application of UV light in TOC digestion of ultrapure water in the pharmaceutical industry

1. Used for drug preparation and dissolution

Ultrapure water plays a vital role in the pharmaceutical industry. First of all, ultrapure water is widely used in the preparation and dissolution of drugs, which is essential to ensure the quality and stability of drugs. Since pharmaceutical products have extremely high requirements for water purity, the use of ultrapure water can effectively avoid contamination by impurities and microorganisms, thereby ensuring the safety and effectiveness of the pharmaceutical process.

2. Effectively remove residues and reduce cross contamination

Ultrapure water can effectively remove residues when cleaning pharmaceutical production equipment and containers, ensuring the cleanliness of equipment and containers and reducing the risk of cross contamination. This is crucial in the pharmaceutical industry because any tiny contamination may have a significant impact on the quality of the drug.

- Laboratory analysis plays an important role

Ultrapure water also plays an important role in laboratory analysis. Many chemical analyses and biological tests require the use of ultrapure water to ensure the accuracy and reliability of experimental results. Using ultrapure water as a solvent can avoid the influence of interfering substances on test results, thereby improving the credibility of the experiment.

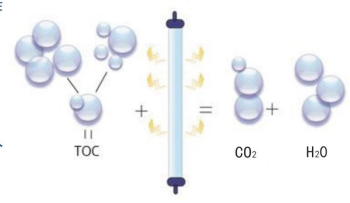

The principle of ultraviolet light removing total organic carbon in ultrapure water

Photolysis : UV photons interact with water molecules, exciting them to generate highly oxidizing hydroxyl radicals (·OH), which can oxidize organic matter in water;

Direct photolysis : high-energy photons directly break the molecular chains of organic matter and decompose organic matter;

Ionization : UV photons break the molecular chains of organic matter, ionize them, and remove them through subsequent ion exchange;

Application and advantages of ultraviolet light to remove TOC in ultrapure water process

High efficiency: UV TOC remover can effectively remove organic matter from water and reduce TOC content.

Environmental protection: No chemical reagents need to be added during the treatment process, avoiding the risk of secondary pollution.

Stability: The equipment operates stably and can work continuously for a long time to ensure the treatment effect.

Small footprint: The equipment has a compact structure and occupies a small area, making it suitable for installation and use in environments with limited space.

Equipment advantages

shell.

Electro-polished 316L stainless steel chambers are available in a variety of configurations to accommodate different flow rates. Optional flange orientations allow the chamber to fit into existing pipe galleries or confined spaces.

UV lamp.

High efficiency, high output lamps are very energy efficient, providing good system performance and reducing power consumption, thus saving operating costs.

Control system.

The controller continuously monitors UV system functions, including safety conditions. Critical and non-critical alarms are generated based on these safety conditions. Critical alarms shut down the UV lamps and drivers. The intuitive 7” touch screen HMI allows the operator to easily configure a variety of settings. The HMI screen displays the status of individual lamps, including detailed parameters.

Modular installation.

Modular rail configuration allows multiple units to be stacked for compact and easily expandable functionality with a reduced footprint.

Advanced control and predictive maintenance.

The user-friendly touch screen interface is easy to use and convenient for operation and monitoring, and can monitor the health of individual lamps and predict whether a lamp will fail. By proactively replacing lamps before failure occurs, general maintenance costs and downtime of the equipment can be reduced.

Technical Parameters

|

Low pressure high intensity UV TOC digestion equipment |

|

| System Features | Low pressure high intensity UV TOC digestion equipment |

| Water treatment capacity | 8-65m³/h |

| Lamp Type | Low voltage high intensity lamp |

| Equipment power | 4kw-30kw |

| Ballast | Electronic ballast, power adjustable |

| Cavity Material | Stainless steel 304/316L |

| Cleaning system | Online mechanical cleaning (not included) |

| Electric control cabinet materials | Carbon steel anti-corrosion/stainless steel 304/316L |

| Monitoring system | Including temperature control and strength detection |

.jpg)

.jpg)

1.jpg)